IMES GmbH

Booth number: N2B4A-07

www.imes.de

About us

The IMES GmbH in Germany, is the leading specialist in the field of combustion engine cylinder pressure and data acquisition systems.

In times where emission regulations continue to tighten, optimised engine performance to reduce NOx and CO2 is of paramount importance. Our high-quality products represent reliability, robustness, durability and long-term accuracy.

The sophisticated sensors, electronic indicators and combustion monitoring systems are employed on a wide range of diesel-, gas- and dual-fuel engines, on ships and locomotives and in power cogeneration plants and pipeline compressor stations all around the world.

Address

Dr.-Herbert-Kittel-Str. 2

87600 Kaufbeuren

Germany

E-mail: info@imes.de

Phone: +49 8341 9661730

Internet: www.imes.de

No. 1465 West Beijing Rd., Jing'an

200040 Shanghai

China

E-mail: info@s-sailing.com

Phone: +86 21 3823-1860

Products & Services

Our cylinder pressure sensors, electronic indicators and combustion monitoring systems offer solutions for engine monitoring and diagnosis for the maritime market.

Continuous online cylinder pressure measurement for advanced engine monitoring and diagnosis, and as an input for closed-loop control systems on gas, diesel- and dual-fuel- engines

Periodic cylinder pressure monitoring by engine operators on propulsion engines, generator sets and compressor sets in ships, power plants and compressor stations

On-site cylinder pressure measurement for research, development, trouble- shooting and periodic cylinder balancing on large engines

All our sensors offer a digital electronic with event storing. They are designed for a minimum of 16,000 operating hours and they have a very good thermodynamic performance. Our products received Marine Type Approval from all significant international classification societies such as Bureau Veritas, DNV, ABS, Lloyd’s Register, RINA, Korean Register and Class NK and also SGS certification for the use in hazardous areas.

EPM Next Generation

The new generation of the successful electronic handheld device EPM offers one common hardware for all EPM types. This enables a simple upgrade from peak pressure indicator EPM-Peak up tp engine analyser EPM-XPplus-vibro.

The measurements the user can perform are depending on the EPM type he is using.

The collected data of all EPM types can be displayed and evaluated from the EPM evaluation software. Depending on the instrument peak pressure, pressure- and combustion behavior, performance data as well as valve timing will be evaluated and analysed.

TCS-01CA PMI

TCS-01CA®-PMI is a two-stroke combustion sensor for continuous measurement of cylinder pressure on two-stroke diesel- and dual-fuel engines (24 hours per day / 365 days per year).

It is specifically designed for the application on electronically controlled engines and suitable as replacement for the standard pressure sensor of PMI-auto-tuning-systems. The connector is pin compatible to PMI systems and the user-friendly plug-and-play-system enables an easy installation.

The sensor is installed in a special designed adaptor between cylinder cover and indicator cock, as this reduces the build-up of combustion deposit at the sensor membrane significantly.

TCS-01CA®-PMI is a very robust sensor and the closed face of the sensor reduces the risk of sooting during long-time operation.

Marine Type Approval:

Bureau Veritas, Class NK, DNV, Korean Register, Lloyd’s Register and RINA.

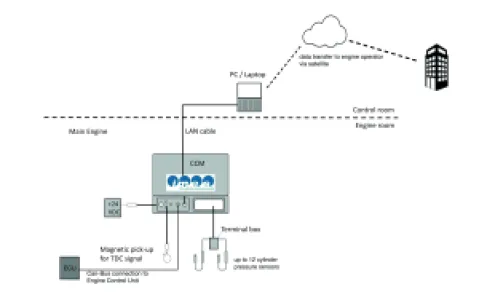

CCM Combustion Control Module

The CCM is an easy to use plug and play system which enables real time data acquisition of cylinder pressure on gas-, marine diesel- and future fuels engines. Data can be recorded from up to 24 cylinders for closed loop control applications and to diagnose malfunctions or to assist in the setting and optimising of engine parameters e.g. balancing cylinder.

CCM evaluates every combustion cycle on every cylinder for to calculate key parameters engine builders need to implement cylinder pressure based control on engines. Its quick data acquisition and recent evaluation software enables extensive analysis about engine performance.

Main functions:

Knock detection

Misfire detection

Calculation of thermodynamic parameters

Peak pressure

IMEP, IPOWER

PSP-01 Pressure Spark Plug – Future Ignition Technology

In 2022 IMES started to develop its own spark plug with an increased service life of 4000 – 6000 hours. In contrast to a known hook spark plug, the design of annular gap shielded with a center electrode as a ring was chosen.

The IMES spark plug type ISP-01 with M18x1.5 screw-in thread has been successfully tested on various gas engines over the last 2 years.

For the integration of a pressure sensor into the spark plug, IMES has developed a miniaturized pressure measuring element that turns two products into one. The pressure spark plug is a future-oriented and innovative product for series use on purged pre-chambers.

By integrating the innovative pressure spark plug into the pre-chamber, the intensity of the ignition flares that go from the pre-chamber into the main combustion chamber can be precisely determined and, with the help of a "closed loop" control circuit, the purge quantity for the pre-chamber can be adjusted directly from working cycle to working cycle. The controlled variable is the pressure gradient in the prechamber, which provides direct information about the lambda in the prechamber.